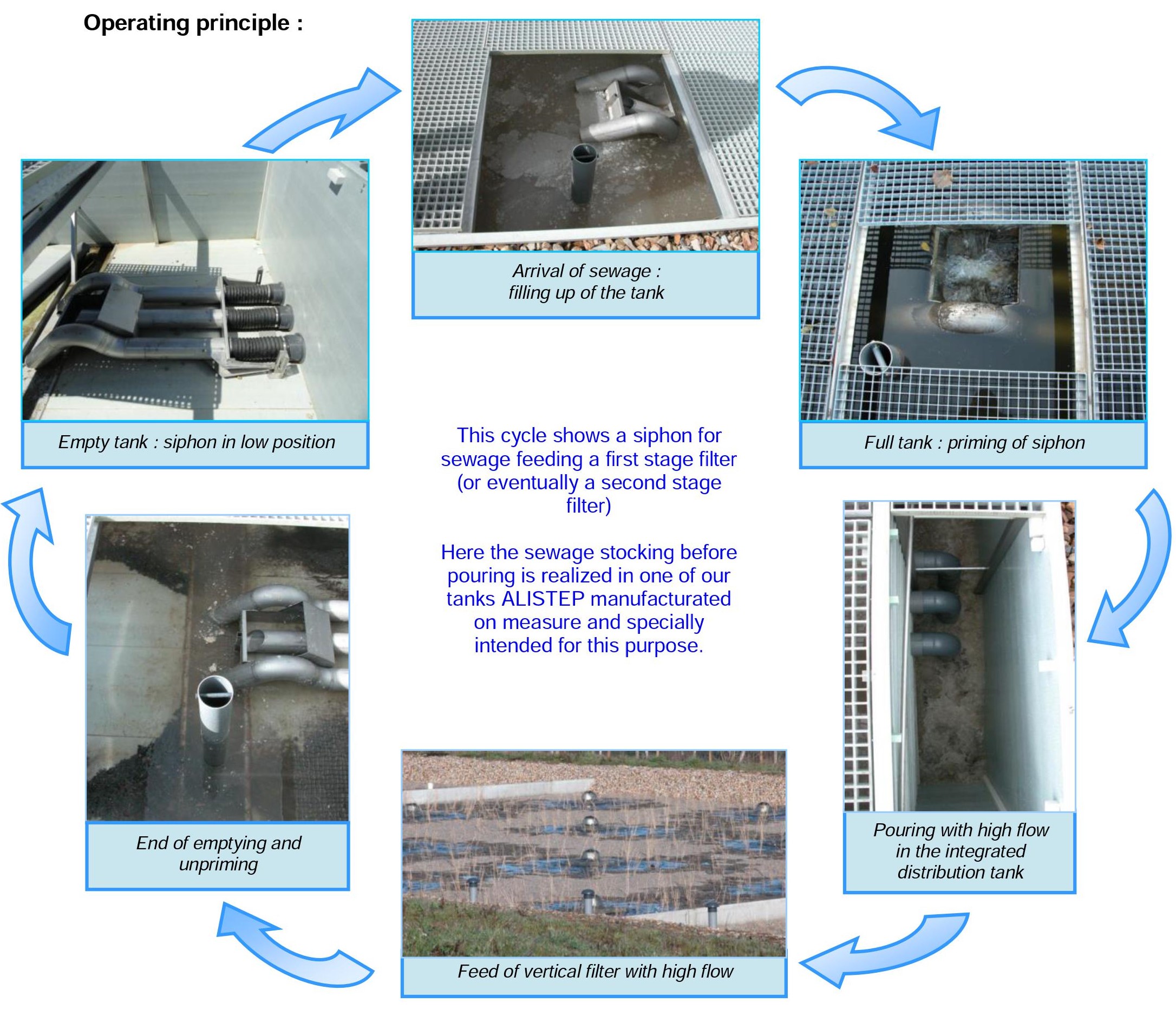

The Alistep Self-priming ball-valve flush for raw sewage, with European patent EP 1524370, allows a high rate of flow to treatment plants for 35 to 2500 EH (equivalent population). It is most commonly used with raw water and is installed upstream of a vertical first-stage filter, which may or may not be planted with macrophytes.

It may also be used with pre-treated water to supply a second-stage filter.

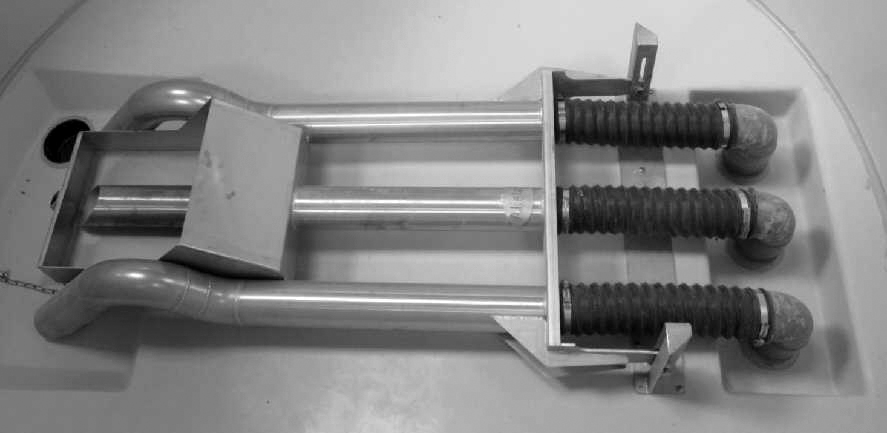

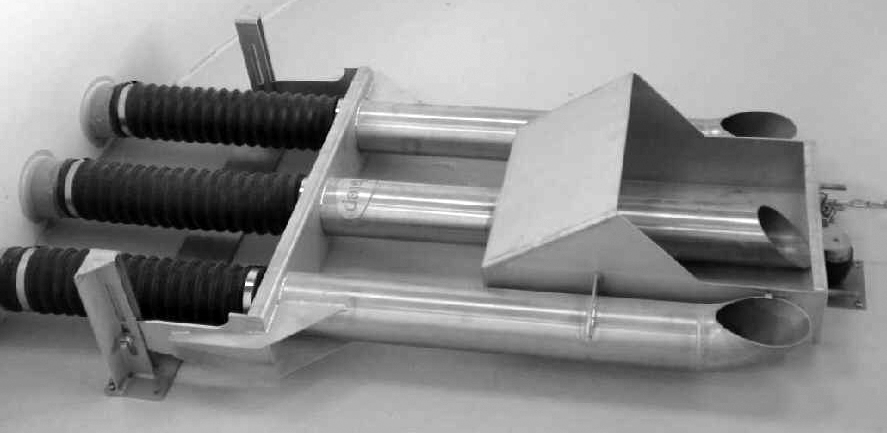

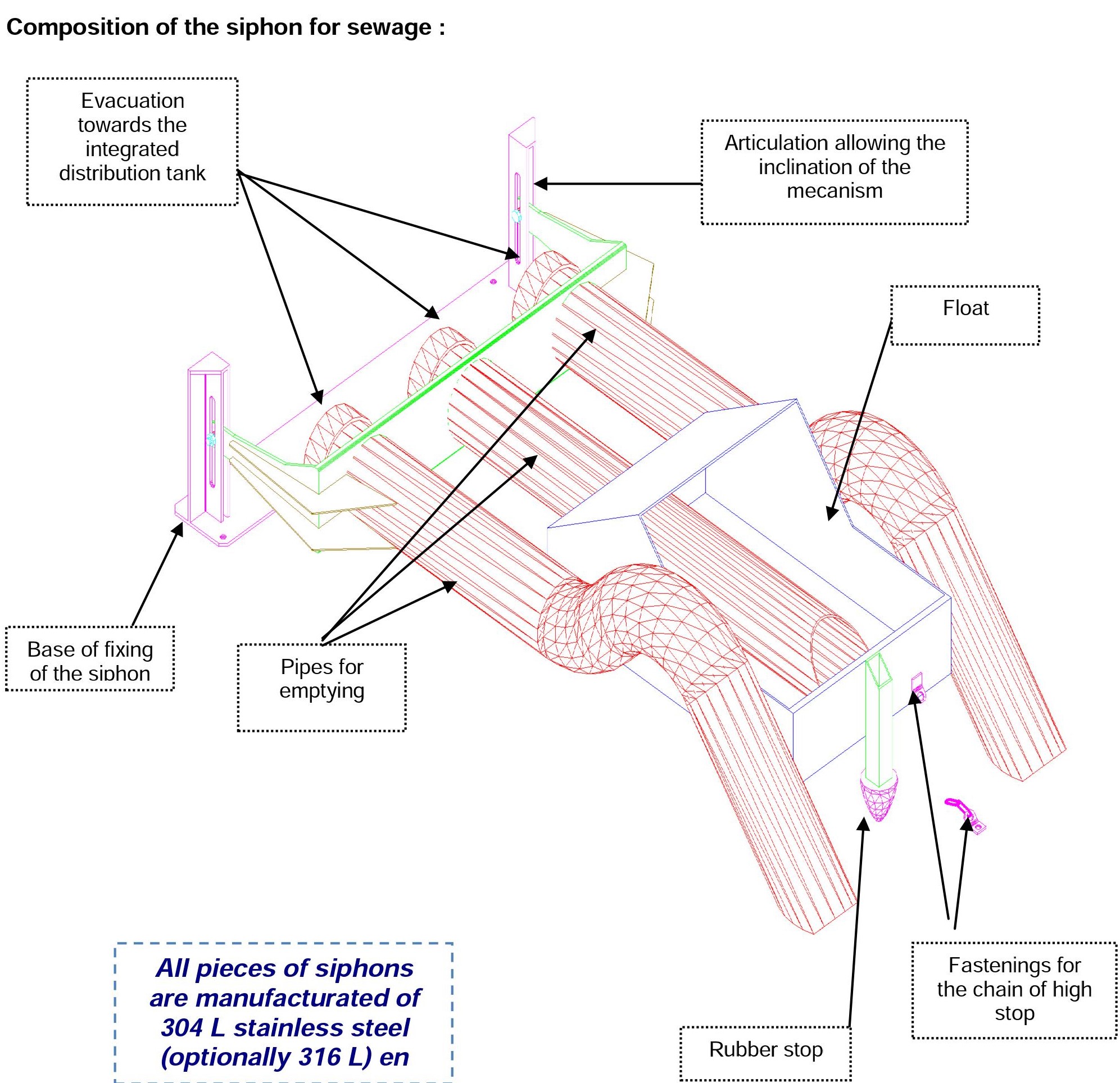

Alistep self-priming siphons are manufactured entirely from 304L (or optionally 316L) stainless steel to ensure a long life, even in corrosive water such as residual urban water.

The Alistep float-operated flush is based on the principle of self-priming siphons and has the main advantage of completely emptying the first-stage tank, removing the need for any pre-treatment (degreasing tank) and special screening conditions (screen size less than 40 mm, pebble trap, etc.). Furthermore, it requires no power supply.

The float tank is emptied by gravity via the central tube ; this is a measure of the reliability of the link between tanks. Also, emptying has been carefully designed to minimise its height in relation to other existing systems, hence a reduced need for a change in levels between the raw water intake and the filters.

To prevent sludge deposits and blockages in the system, the lateral emptying arms on the Alistep raw water emptying mechanism ensure that the tank empties completely.

The system is low maintenance requiring only that the system is rinsed with clean water once a month.

Since the first-stage tank is emptied completely, the system is low maintenance : the siphon and tank require rinsing with clean water once a month.

Our siphons guarantee average flow rates of 60 to 200 cu. m. per hour, even more, if required.

|

Pipe diameters

|

Flow rate commonly used

|

|

88,9 mm

|

60 cu. m. per hr

|

|

114,3 mm

|

120 cu. m. per hr

|

|

139,7 mm

|

200 cu. m. per hr

|

In addition to these generic models, our flushing devices can be CUSTOM manufactured.

Their modular design allows them to be adapted to meet all levels of need) extending the flushing device, adding lateral arms, increasing pipe diameters, etc.)

DEMO VIDEO |

Adjusting of the chain

Flexible hose change

Installation of the pendular syphon

Adjusting of the pendular syphon